THE FACILITY

WHERE EXCELLENCE IS CASTED

Aneya Foundries Pvt. Ltd.operates out of a state-of-the-art facility spanning 50,000 square feet. Our infrastructure is meticulously designed to uphold our commitment to excellence, quality, and innovation in casting solutions. Strategically located in Vasai,

just 44 km from Mumbai airport

our facility ensures efficient access for both local and international clients. The expansive layout is optimized for large-scale projects and seamless workflow, from initial design through to final product delivery.

STORES

Our stores play a crucial role in maintaining operational efficiency. Highlights include:

Inventory

Management

A well-maintained inventory of raw materials ensures swift response.

Organized

Storage

An efficient inventory system and specialized storage areas for various materials help streamline workflow and facilitate easy access.

Material

Handling

Proper conditions for material storage and retrieval support high-quality casting and machining processes.

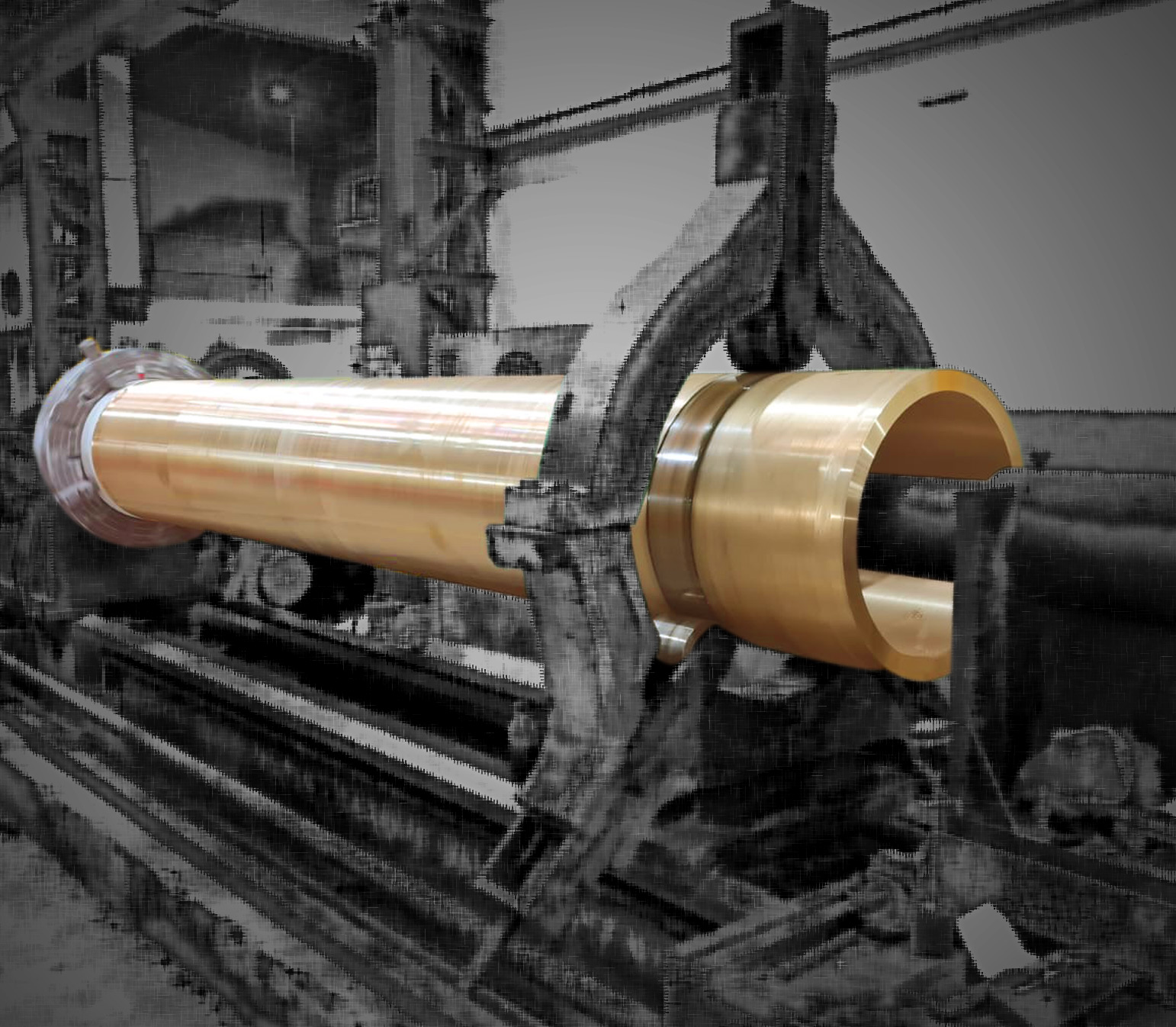

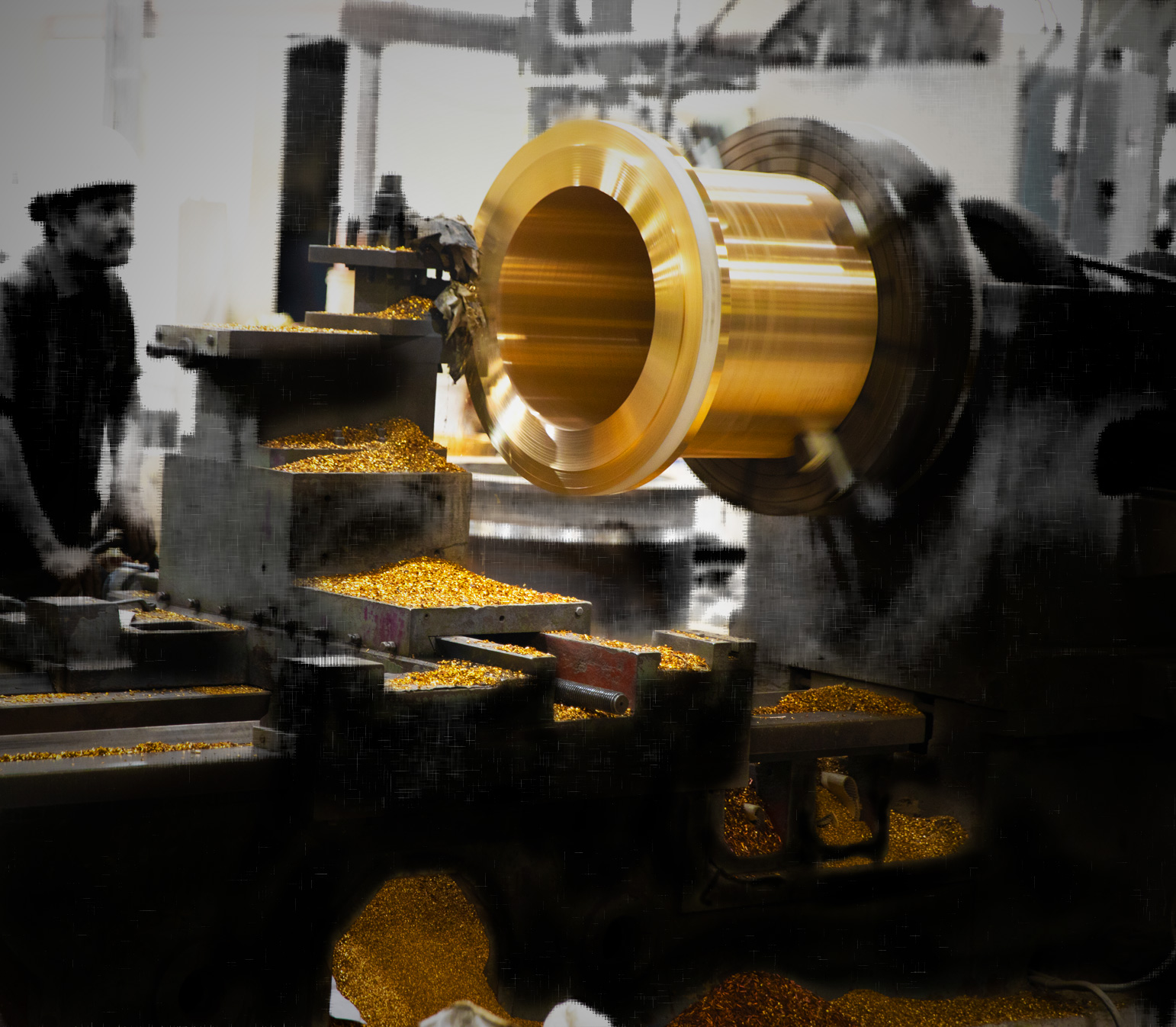

MELT SHOP

The melt shop is the core of our foundry, equipped with advanced technology for

producing high-quality ferrous and non-ferrous castings. Key features:

Diverse Furnaces

Automated systems ensure accurate temperature and composition control, maintaining consistent metal quality.

Precision Control

Continuous upgrades to our furnaces and casting equipment enable us to produce high-precision ferrous castings with consistent quality.