THE RANGE

OUR RANGE OF EXCELLENCE

At Aneya Foundries Pvt. Ltd. (AFPL), we take great pride in offering a diverse array of casting solutions designed to meet various industries' specific requirements. Our expertise in centrifugal casting has been a cornerstone of our success, reflecting our commitment to precision and innovation. Building on this solid foundation, we are expanding our capabilities to include sand and ferrous casting, ensuring we provide a complete range of solutions to address our clients' diverse needs.

Our commitment to excellence drives us to continuously evolve and adapt, enabling us to offer comprehensive casting solutions that cater to different industry demands. Whether you require the precision of centrifugal casting or the robustness of sand and ferrous casting, AFPL is dedicated to delivering high-quality, customized products that exceed expectations and drive success for our clients.

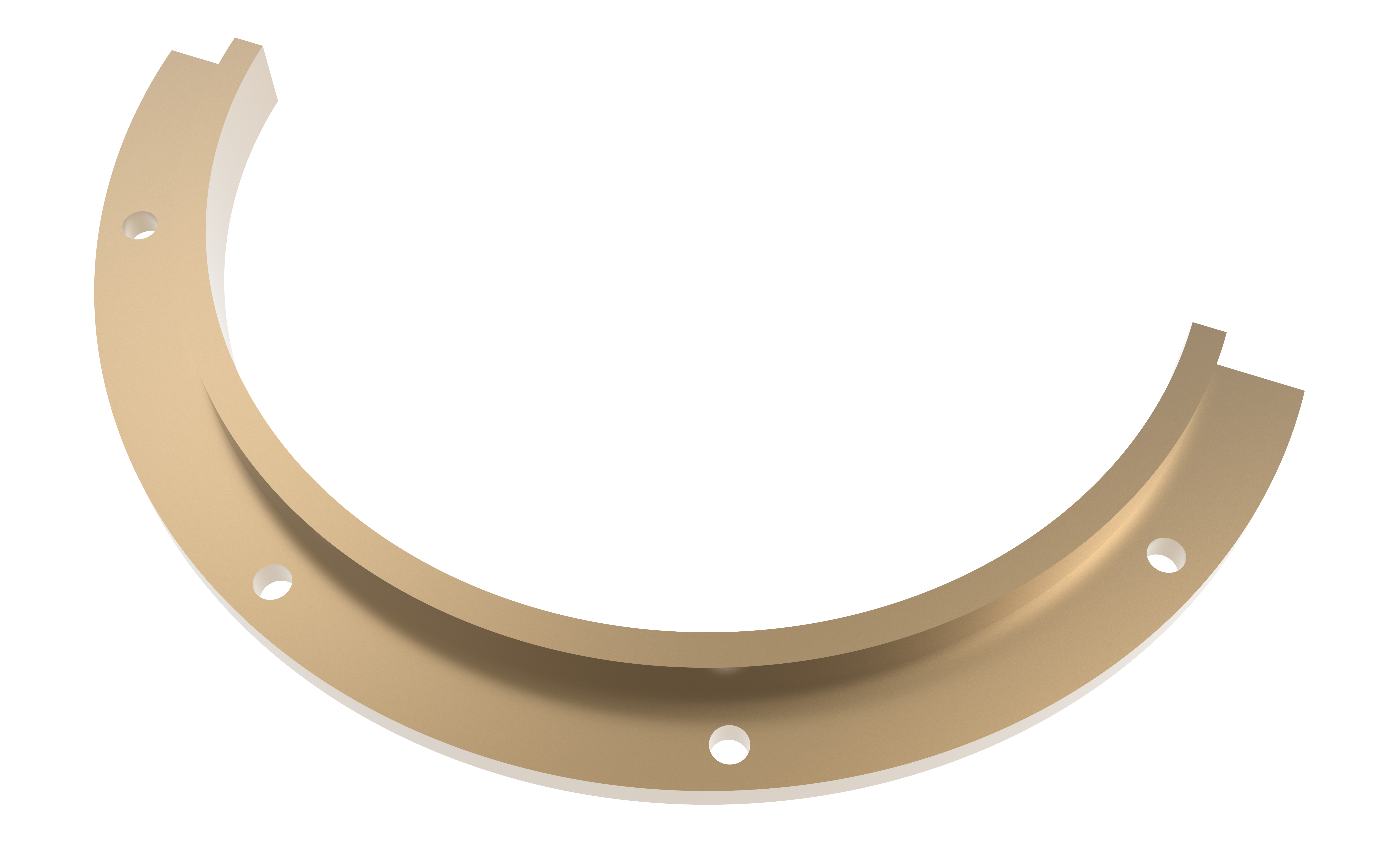

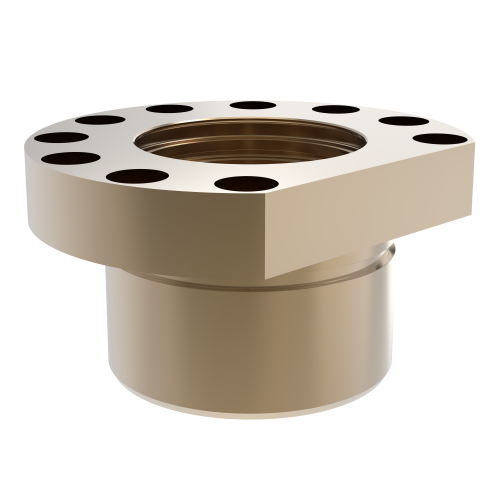

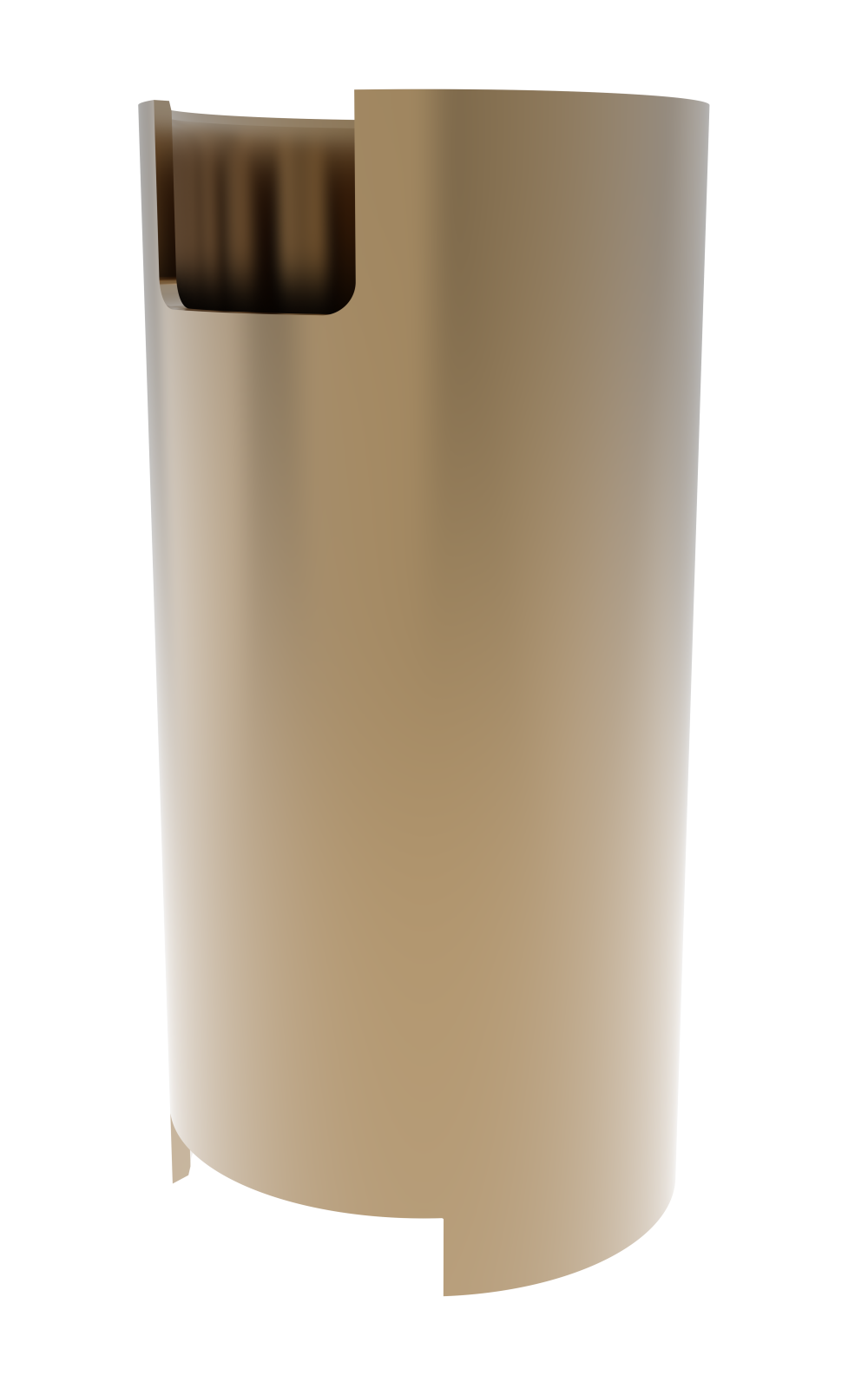

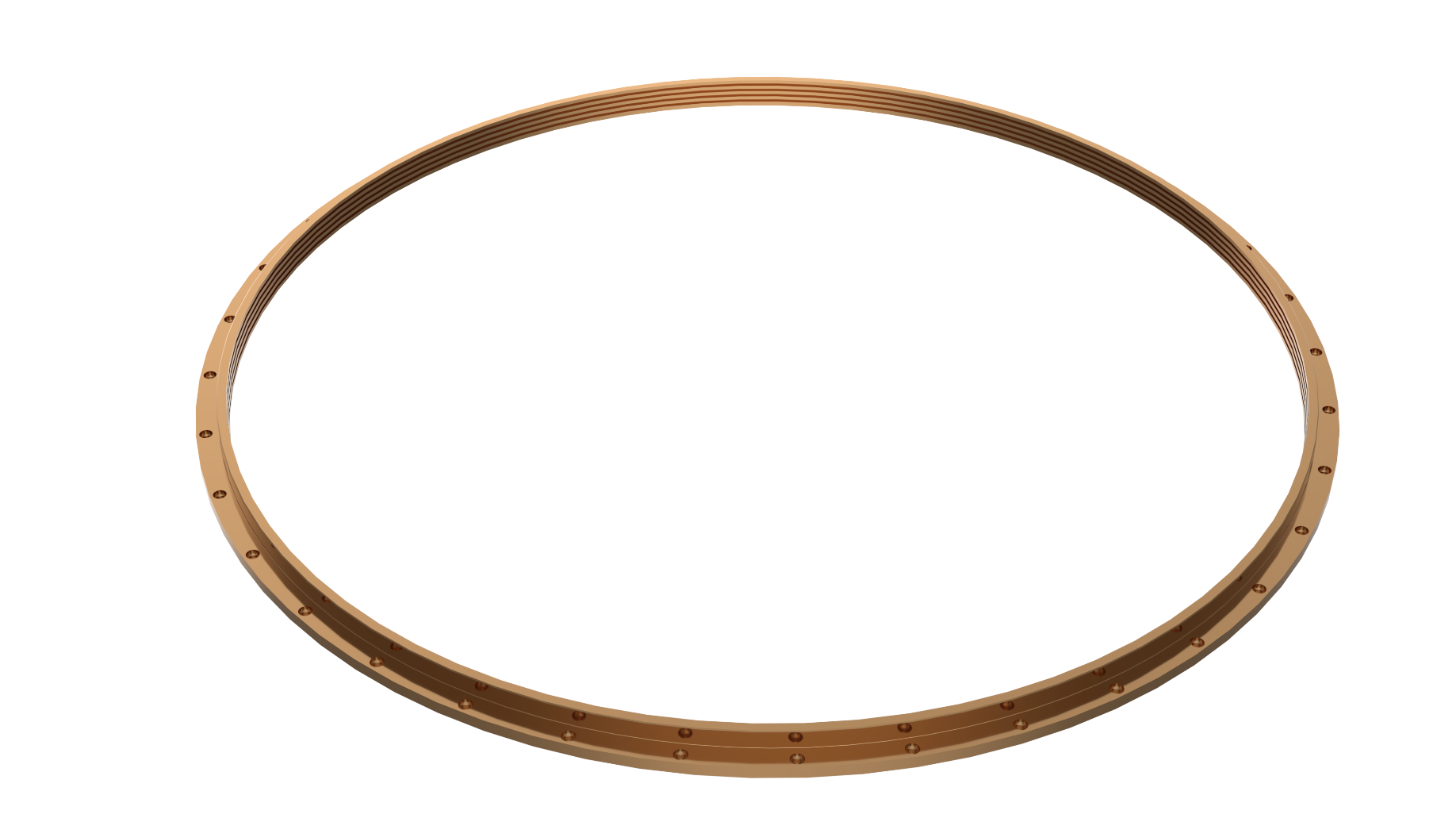

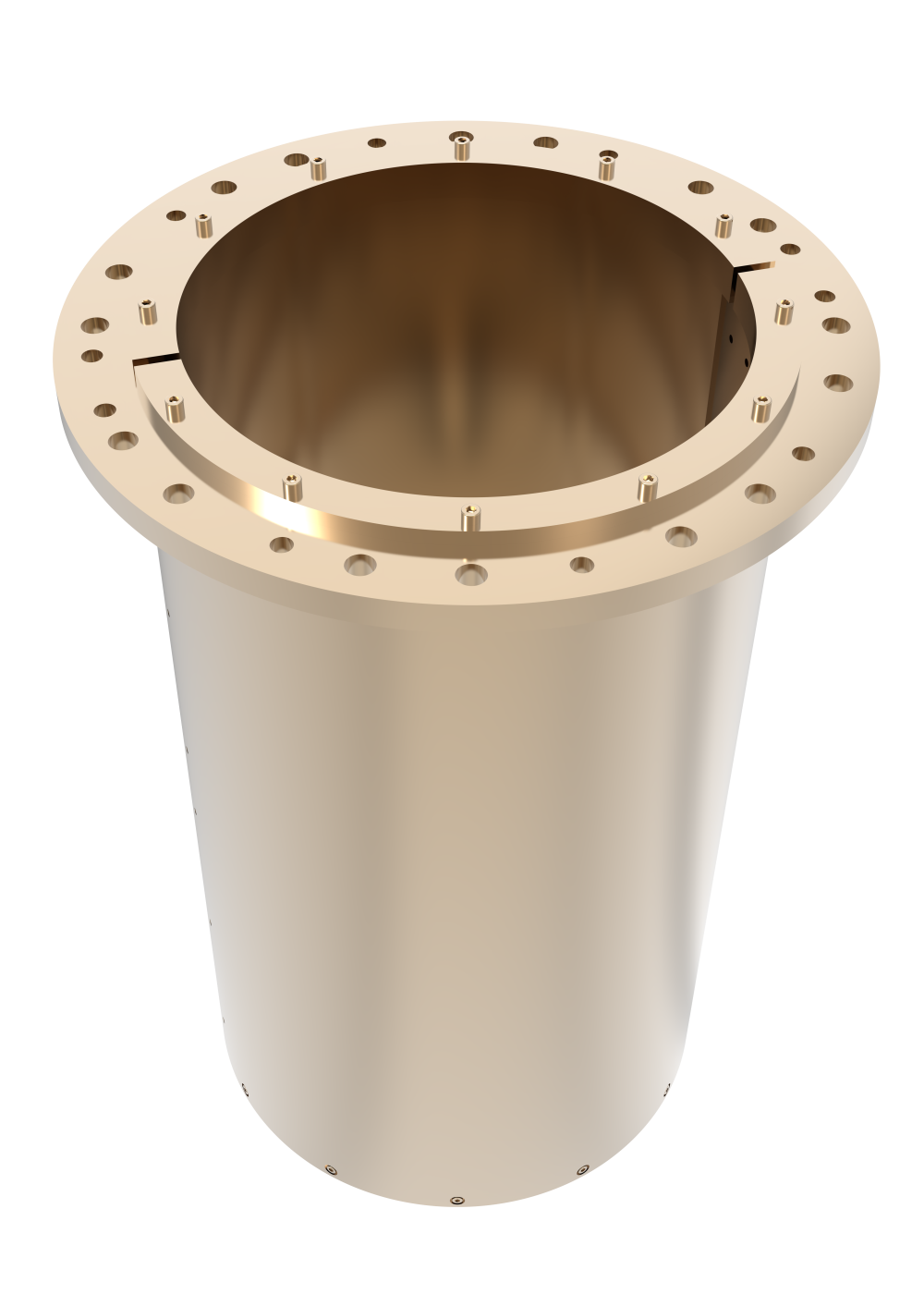

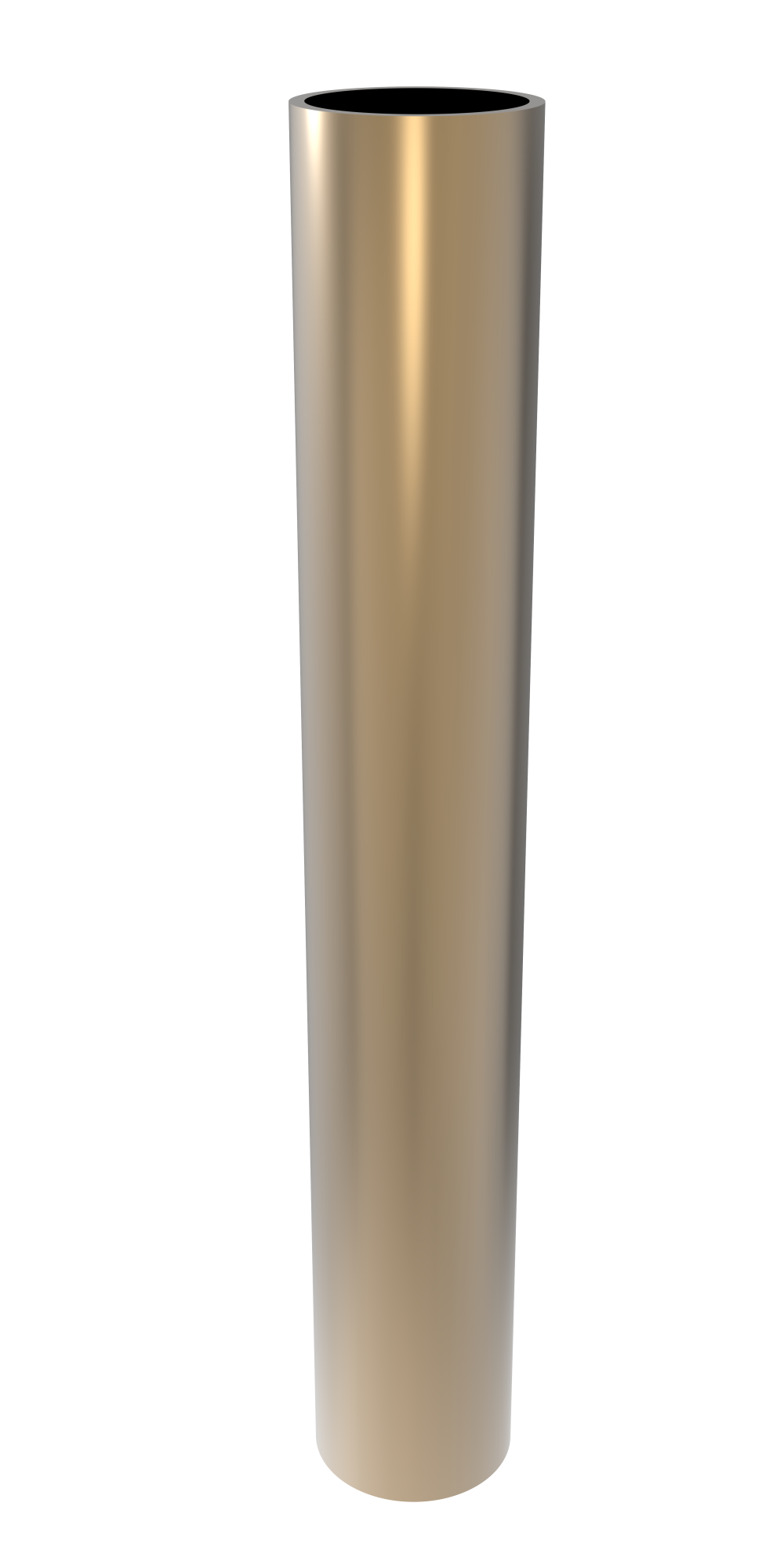

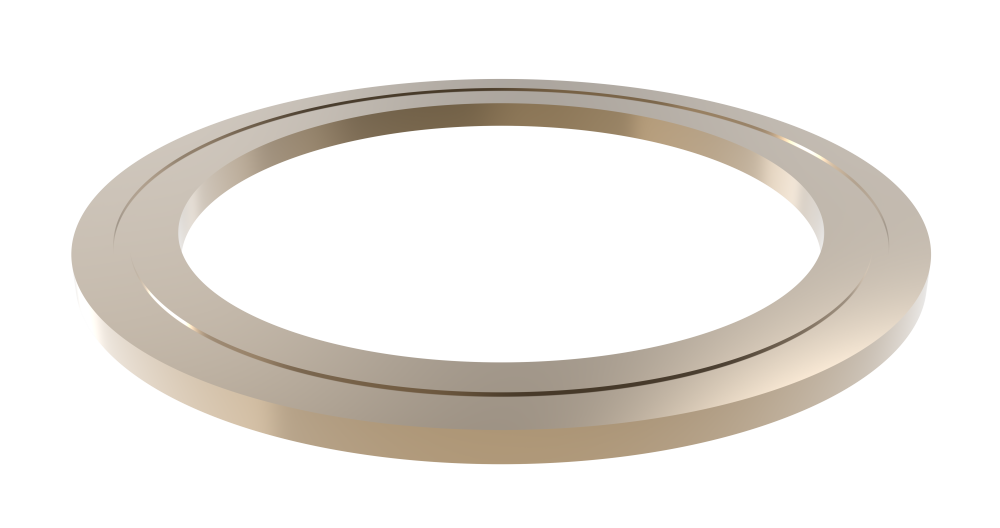

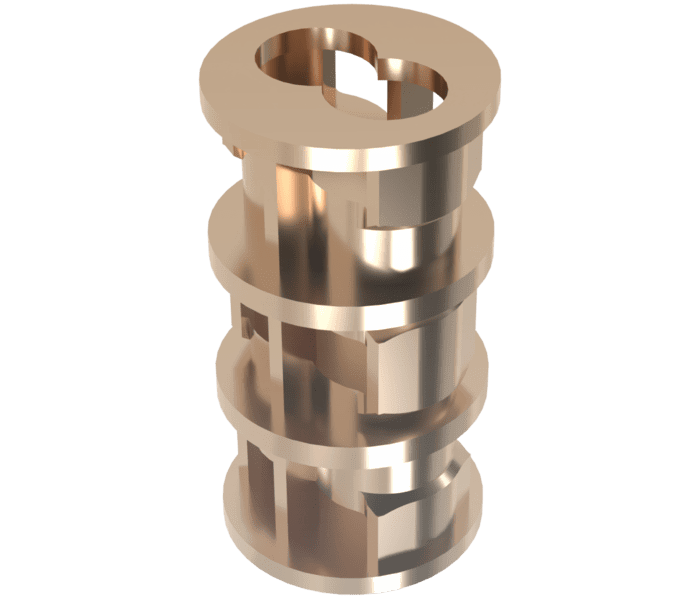

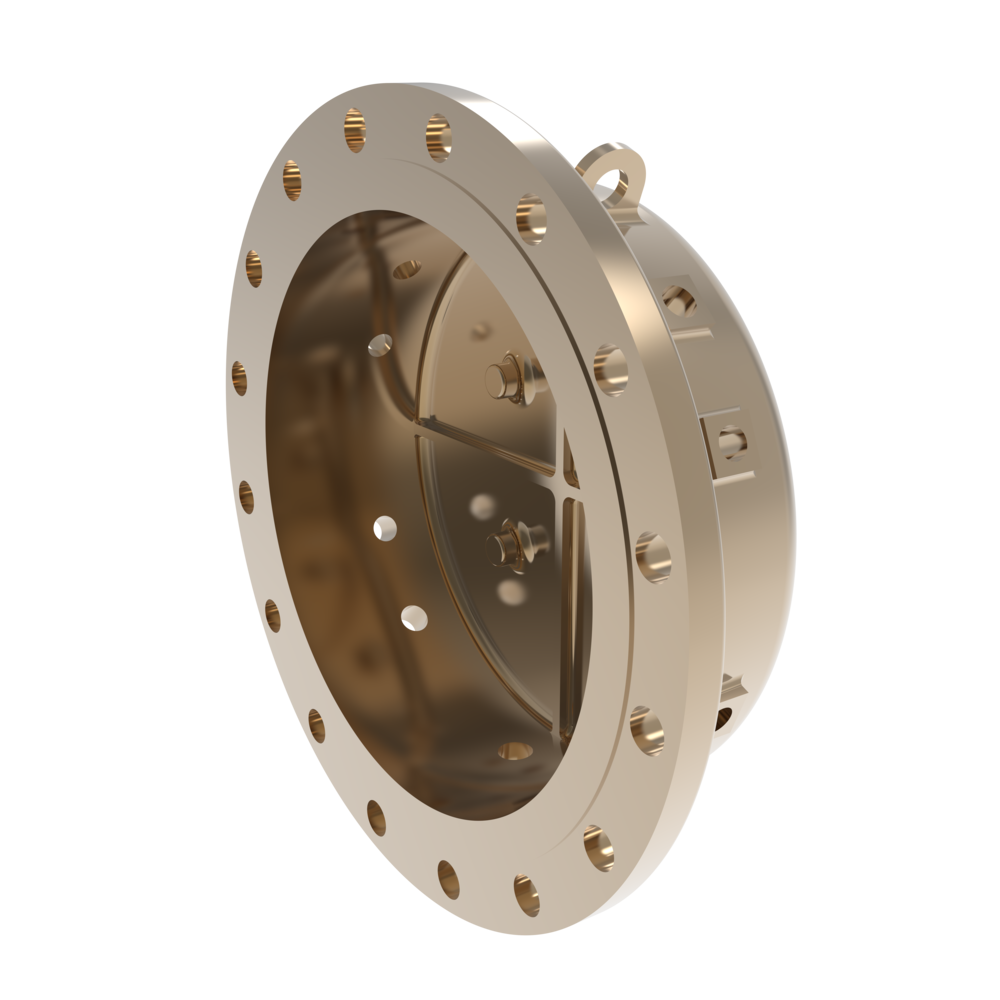

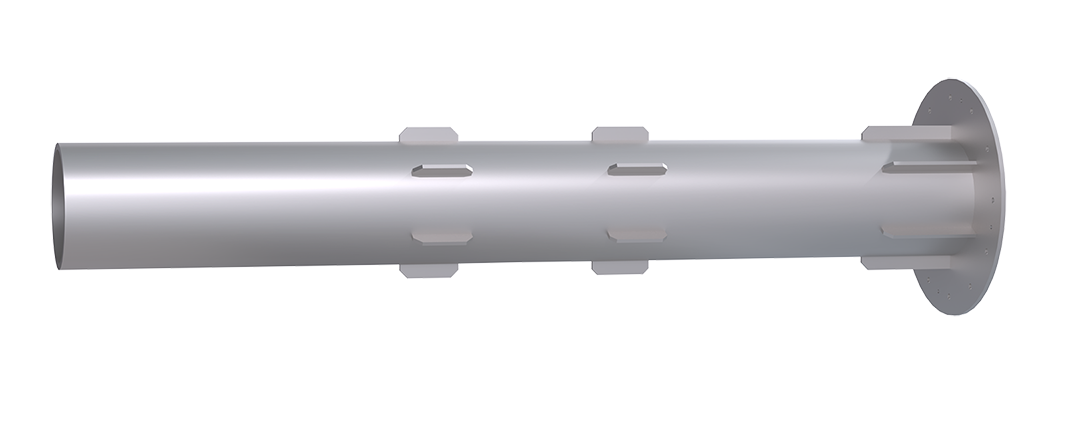

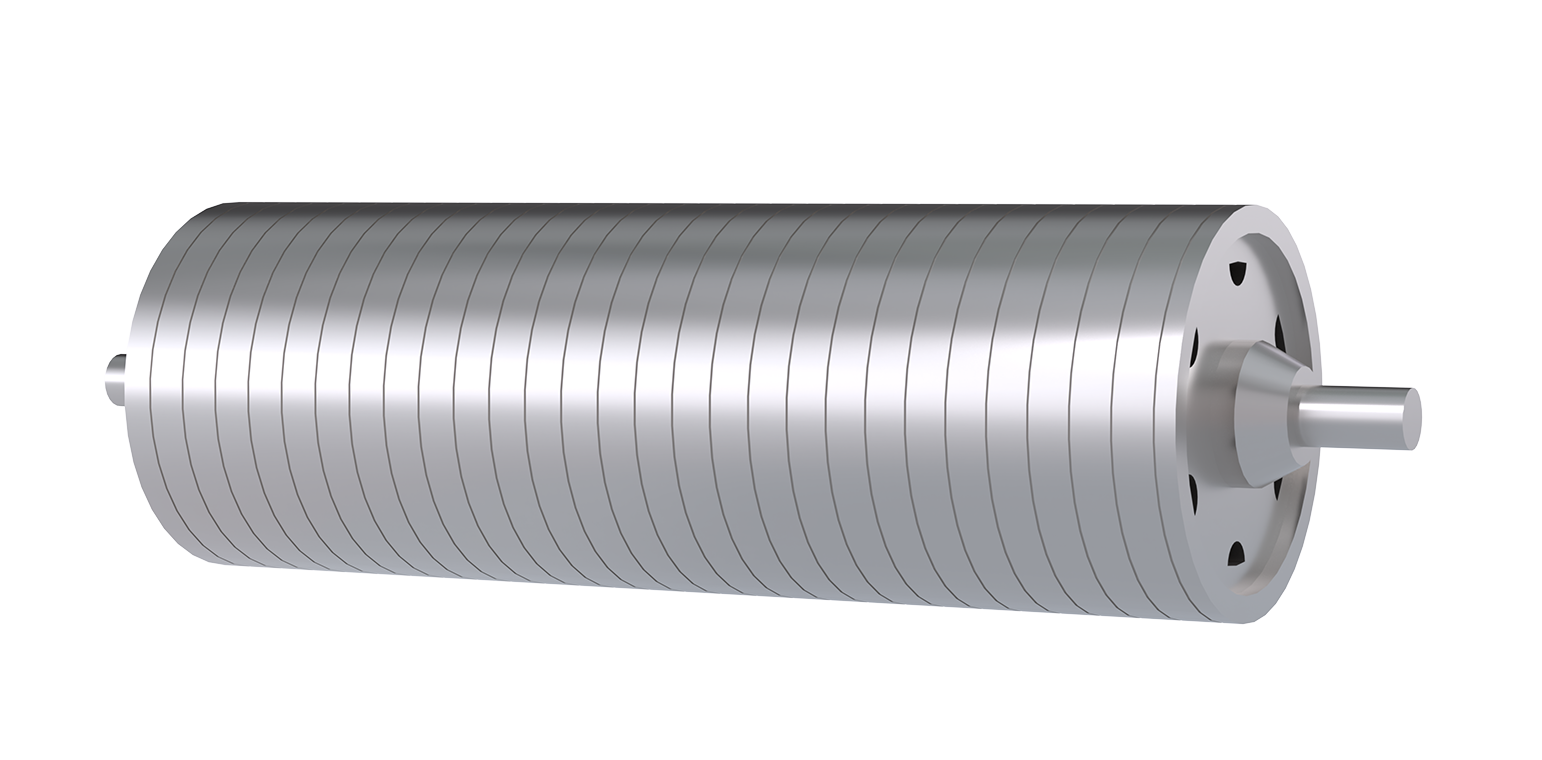

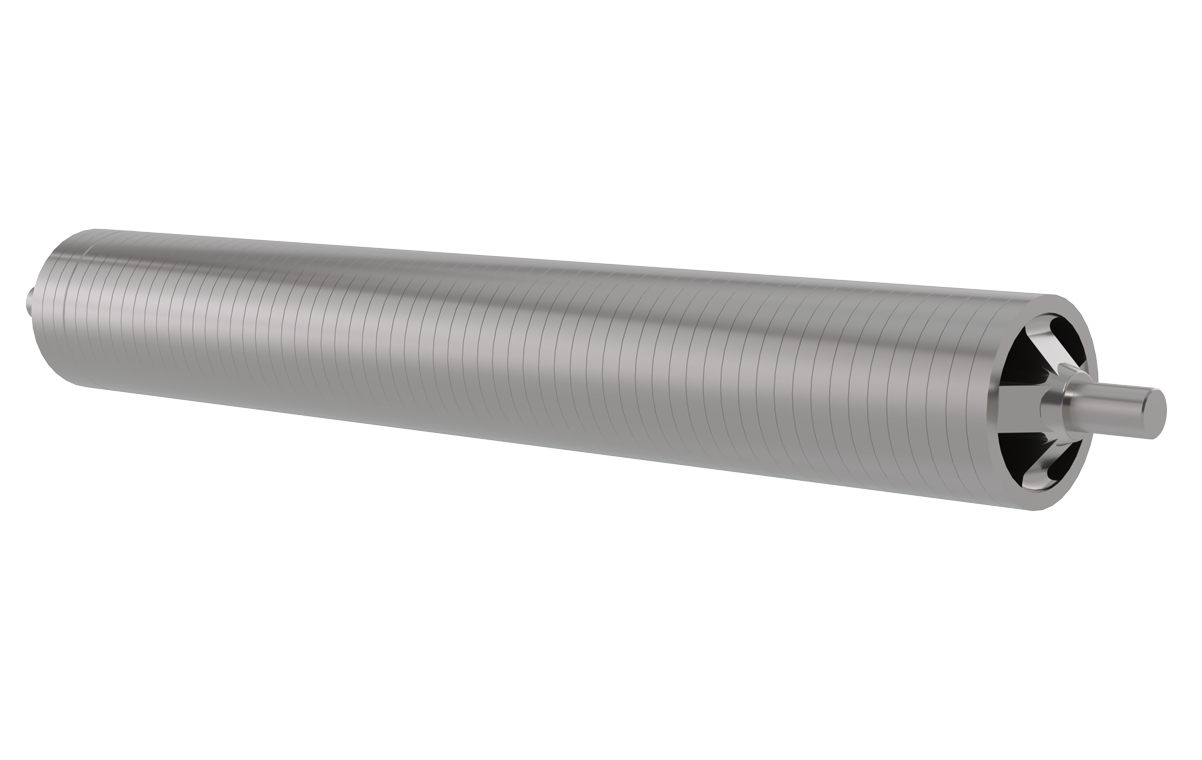

CENTRIFUGAL CASTING

Our centrifugal casting process showcases our deep expertise and advanced technology. Key features include:

Versatility

We handle a broad range of metals, including bronze alloys, copper alloys, stainless steel, and more. This versatility allows us to produce components that meet specific performance requirements across industries like marine, defence, and power generation.

Precision

Utilizing state-of-the-art centrifugal casting machines, we achieve exceptional dimensional accuracy and uniformity. This ensures that our castings meet stringent industry standards.

Quality

The centrifugal force used in the casting process helps to eliminate impurities and porosity, enhancing the strength and durability of the final product.

Non-ferrous Metal Grades

Tin Bronze, Aluminium Bronze, Phosphor Bronze, Leaded Bronze, Gunmetal and other alloys of Copper.

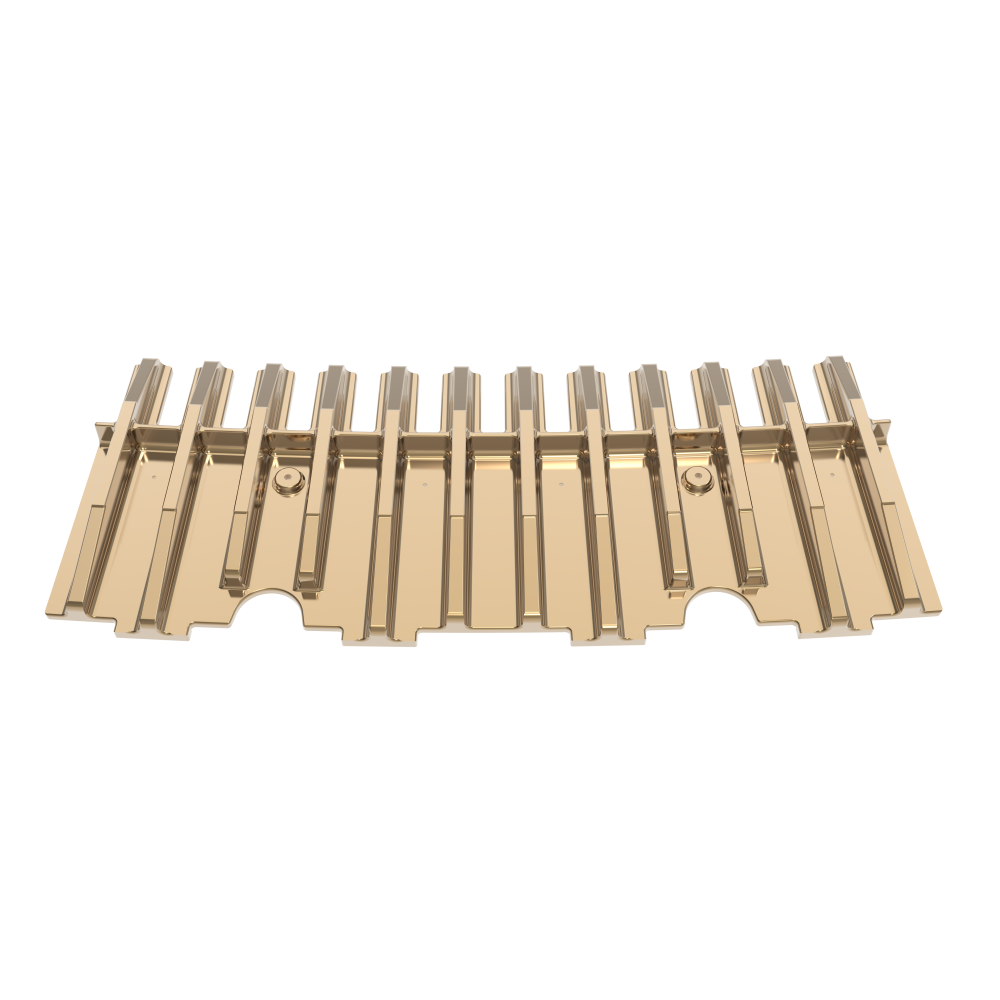

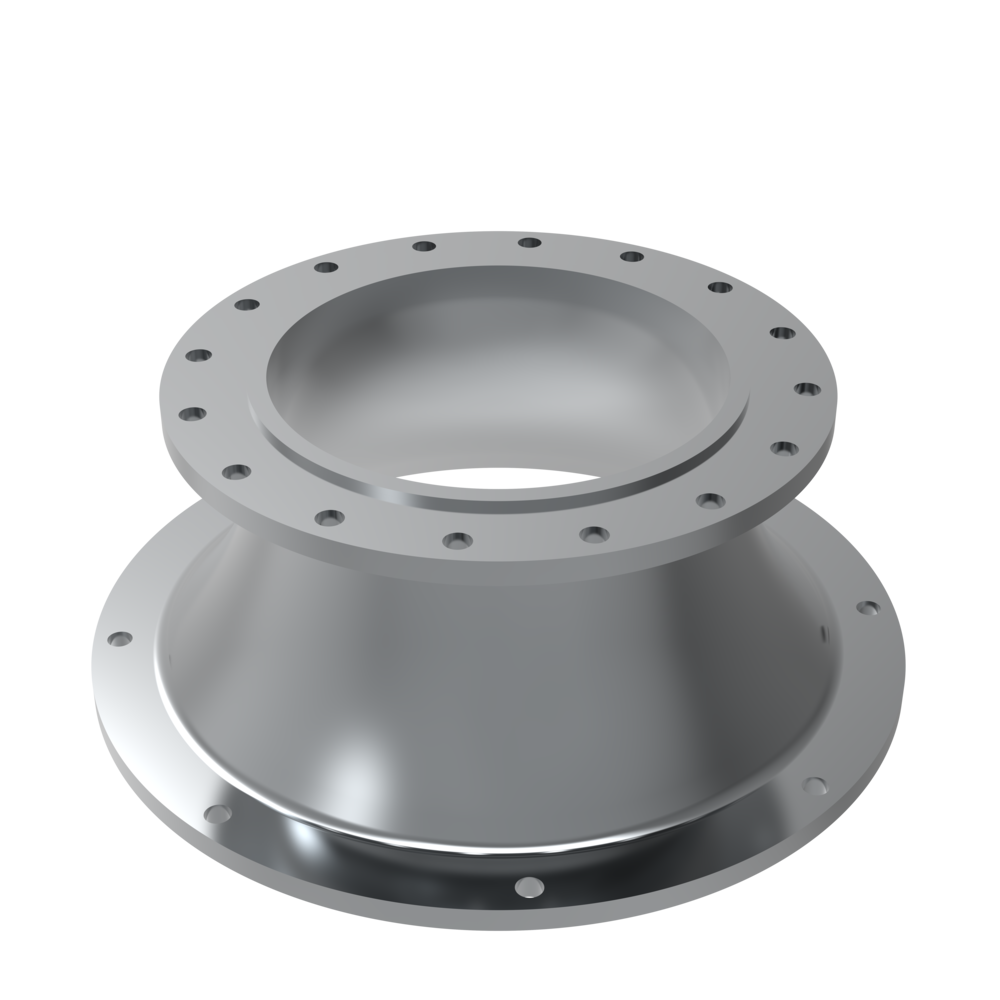

SAND CASTING

As we expand our offerings, sand casting has become a focal point of growth for AFPL. Highlights of our sand casting capabilities include:

Flexibility

We produce castings of various sizes, from small components to large structures, accommodating diverse design specifications and industry standards.

Customization

Our dedicated team works closely with clients to develop custom sand casting solutions, ensuring that each casting meets specific performance and reliability requirements.

Efficiency

Advanced moulding and core-making equipment are employed to streamline our sand casting processes, delivering high-quality products within competitive timelines.

Non-ferrous Metal Grades

Tin Bronze, Aluminium Bronze, Phosphor Bronze, Leaded Bronze, Gunmetal and other alloys of Copper.

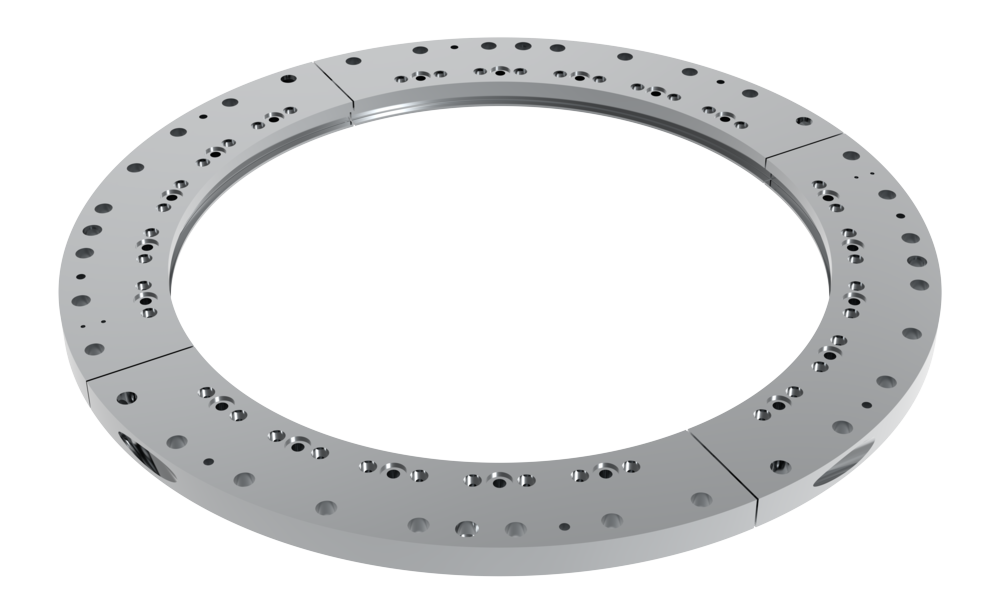

FERROUS CASTING

Our foray into ferrous casting reflects our commitment to quality and innovation. Key aspects of our ferrous casting services include:

Material Expertise

We work with a range of ferrous metals, including various grades of stainless steel and superalloys. This expertise allows us to produce components with excellent mechanical properties and wear resistance.

Advanced Techniques

Continuous upgrades to our furnaces and casting equipment enable us to produce high-precision ferrous castings with consistent quality.

Quality Assurance

Rigorous testing and inspection processes are in place to ensure that our ferrous castings meet the highest quality and performance standards, delivering reliable and durable components.

Ferrous Metal Grades

Stainless Steel 300 series, Stainless Steel 400 series, Duplex, Super Duplex, Superalloys and more.